Coating Series Equipment

| Coating method | Viscosity | Wet thickness | Coating machine speed | Coating width |

|---|---|---|---|---|

| Direct Gravure | < 2000 cp | < 40 μm | < 300 M/min | < 1700 mm |

| Reverse Gravure Coating | < 1000 cp | < 30 μm | < 250 M/min | < 1700 mm |

| Offset Gravure Coating | 1~3000 cp | < 10 μm | < 300 M/min | < 1700 mm |

| Micro Gravure | < 1000 cp | < 30 μm | < 300 M/min | < 1700 mm |

| Flexo Coating | 1~500 cp | < 10 μm | < 400 M/min | < 2000 mm |

| Four Roller Coating | < 4000 cp | 0.8 μm~ 30 μm | < 250 M/min | < 1500 mm |

| Slot Die Coating | < 50000 cp | 3 μm~ 100 μm | < 150 M/min | < 1300 mm |

KYMC offers two different coating applications which are roll application and pre-metered application. To decide which method to apply, one can reference the criteria list below to help make the decision.

Contamination control:

When the coating requires contamination control, then the pre-metered method is recommended. However, if the coating can accept a small number of debris and contaminants from the environment, then the roll application is recommended for quick change over.

Precision control:

When a very precise coating laydown amount and uniformity are required, then the pre-metered method is recommended. When the laydown amount and uniformity requirement are less stringent, then the roller application can be adopted for a faster coating speed.

Flexibility requirement:

When the viscosity level and coating thickness working ranges are wide, then the pre-metered method is recommended. When viscosity level and coating thickness ranges are more stable within a small range then the roller application is recommended.

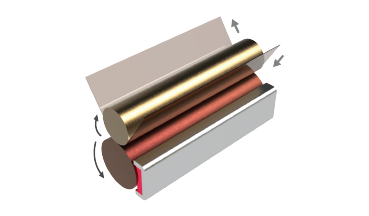

Direct Gravure Coating

Application

For a high viscosity level coating that does not require a precise uniformity at high coating speed. Suitable for higher thickness coating requirements.

Product

leather, textile, wallpaper, architectural materials, tape, insulator, packaging

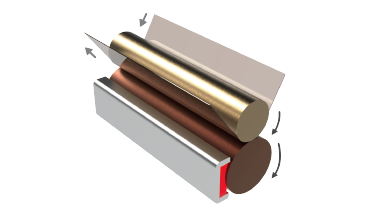

Reverse Gravure Coating

Application

For a medium viscosity level coating that requires more precision and a smoother coating.

Product

leather, textile, wallpaper, architectural materials, tape, insulator, packaging

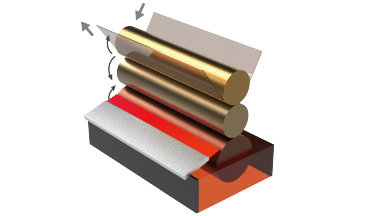

Gravure Offset Coating

Application

For an application that requires more control and flexibility over the coating thickness and weight. Suitable for thinner thickness coating requirements.

Product

tape, insulator, packaging, electronics

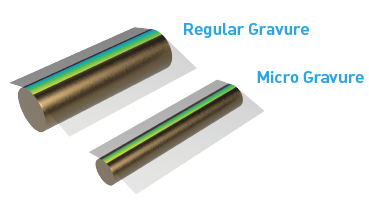

Micro Gravure Coating

Application

When compared to regular gravure coating, the micro gravure coating has a smaller application roller diameter. This allows for an exceptionally stable coating that is thin and uniform. A reverse micro gravure coating can be applied for a even smoother coating surface when compared to the direct micro gravure coating.

Product

tape, electronics

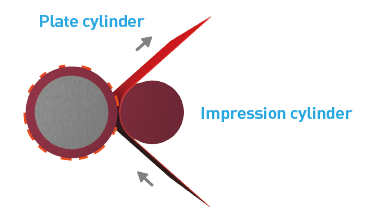

Flexo Coating

Application

For a low viscosity level coating that does not require a precise uniformity at very high coating speed. Suitable for thinner thickness coating requirements.

Product

tape, insulator, packaging, electronics packaging

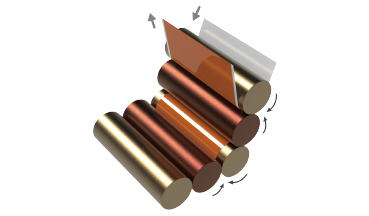

Four Roller Coating

Application

For a high viscosity level coating that requires precise uniformity, and at the same time needs the control and flexibility to provide a wide range of coating thickness. It has the ability to lay down a very thin layer of coating.

Product

tape, insulator, packaging, electronics packaging

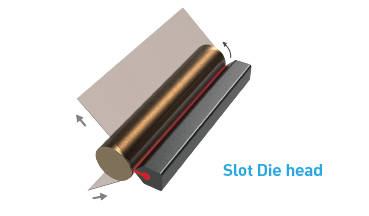

Slot Die Coating

Application

Suitable for the widest range of viscosity level requirement and coating thickness requirement. Slot die coating is for those who are looking for a maximum control, precision and flexibility.

Product

optical, semiconductor protective films, battery, electronics packaging