Technical

| Subject | Images |

|---|---|

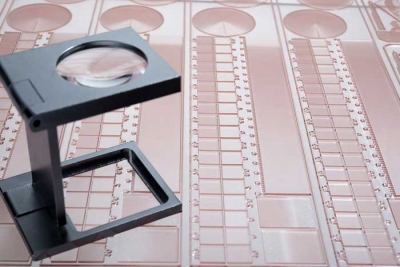

Why is an accurate ink viscosity crucial? How to effectively control the ink viscosity? The types of viscometers available to measure viscosity will be discussed.

There are several purposes of coating over a print. To provide a protective layer over the print, or to provide a separation layer between the packaging and the product. To help to keep the product fresh. To enhance the graphical image, helping the brand stand out from the crowd. If you are already using UV coating, or if you are a high coating usage user, then you consider the UV-LED coating methodology. There are several advantages to the UV-LED coating that sets it apart from UV coating. Let’s look more deeply into it through its technical properties and environmental impact.

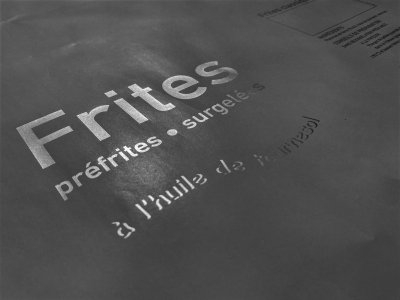

As technology advances printers from the flexible packaging industries are provided with more choices to select from. Inks and their drying methods are among one of the categories where printers have gain access to a variety of selections. The solvent-based ink, water-based ink, UV ink, EB ink…etc. Today we are going to discuss about UV-LED and its curing(drying) method. To explore the benefits and at the same time its disadvantages so that printers can obtain an unbiased review on the UV-LED technology. Advantages: leveraged operation efficiencies, increase business opportunities, higher print quality, more environmentally friendly. Disadvantages: higher cost, shorter ink shelf life.

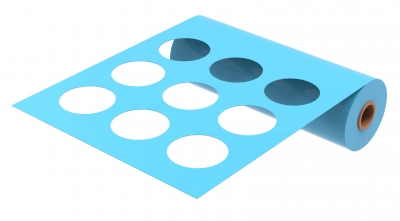

It’s all about the application! Now, there is a better way to produce window packaging, modified atmosphere packaging (MAP) and easy-tear stripes on the packaging. By better, we mean greater flexibility, greater accuracy, faster, less waste, and less maintenance. KYMC is working with laser solution providers to provide our customers with the capability to meet the market application needs in a better way.