Wide Tension Range Flexographic Press

Having a good control of your web tension is crucial as it will impact the print result directly. Some of the issues that may arise due to an incorrect web tension includes, register out of tolerance, winkle of the material, curl up of the material, slippage of the material, and stretching or even breaking of the material.

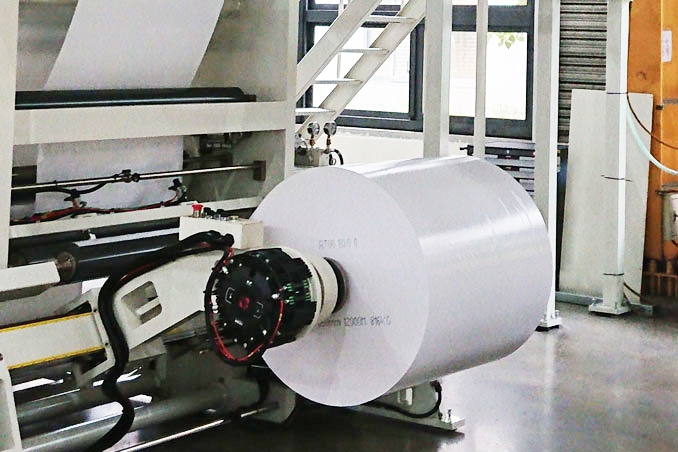

To provide a stable and correct tension through out the printing process, the KYMC press uses motor as the break control at the unwind stations. Furthermore, tension could be controlled either through speed or through torque, depending on the working material. Load cells and dancing rollers are included to help with the precise tension adjustment and tension measurement.

Tension control can be broken down into 3 different zones, unwind, internal and rewind. The tension of the material can be calculated by the formula: Tension = Torque / Roll Radius. As production continues, the unwind roll becomes smaller and smaller, therefore the torque applied will need to decrease to maintain the same tension. At the rewind station, the roll becomes larger and larger, therefore the torque will need to increase to maintain the same tension. Usually, a constant tension is desired at the unwind zone and at the internal zone, but with a dynamic tension level at the rewinding zone. The reason for the maintaining a dynamic tension level at the rewinding zone is because when the web is rewinded at the end of the production. Each layer builds up compressive forces which can cause the inner layer to be stretched and wrinkled. Therefore, the tension will need to be gradually reduced as the rewind rolls build up. This process is called the Taper tension.

At KYMC we are experienced in the control of web tensions. Sufficient sensors are placed throughout the press to measure the tensions at the different zones. The press filters any disturbance in the tension, so it doesn’t get carried over to the next phase of the printing press. The ideal automatic tension control system on a KYMC press gives the press operator one less thing to worry about. The operators set up the running tension and the press will automatically take care of the rest.

Relevant Reading

Wide Web Flexo Press – Setup Operation

Should I use a motor or brake for web tension control?

Article by Daywey Chen, KYMC