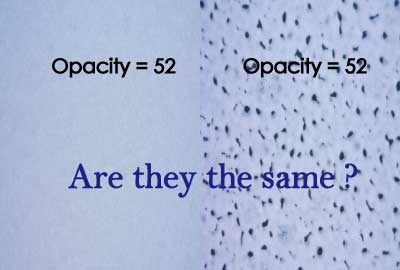

Is it enough to have a high opacity for your white ink laydown?

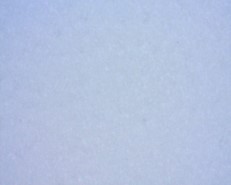

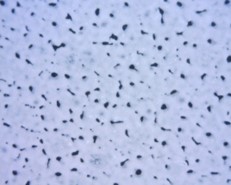

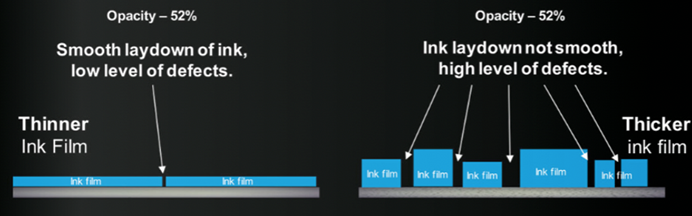

So what is the opacity for the white ink laydown background? This is a common question that people ask when trying to identify the quality of the white ink laydown in Flexography. Opacity is definitely one of the metrics for measurement. However, it only tells part of the story. It is possible to have two prints with the same opacity reading but differs in print quality. The reason is that opacity alone does not measure the smoothness or uniformity of the ink laydown. Figure 1 and Figure 2 below have the same opacity reading of 52 percent. However, it is obvious that the print quality of Figure 1 is better than Figure 2. Figure 1 does not contain the print imperfections such as pinholes and uneven ink laydowns. Figure 3 is another illustration showing how print with the same opacity can have different quality from an enlarged side view angle. Therefore, we need to add the measurement of mottle and graininess to the equation to better evaluate a print.

Figure 1

Figure 2

Figure 3

Print opacity is a measurement of the amount of light transmission. A complete opaque print means that no light will pass through it, having an opacity of 100. A completely transparent substrate will have an opacity of 0.

Print mottle is when a print image visually appears to be blotchy, streaky, or non-uniform caused by uneven ink laydown. Graininess describes a visual that is similar to mottle but at a micro-level, zooming down to the unevenness of tone in halftone dots.

The level of mottle and graininess can be calculated by breaking down the print image into small square pieces. The square pieces are compared against each other, and a difference level is statically represented by the standard deviation of those squares as shown in Figure 4. The smaller the standard deviation, the better the print quality.

Figure 4

Together, print opacity, mottle reading, and graininess reading form a multi-dimension measurement system to better evaluate the quality of the white ink laydown.

Source: https://www.flexography.org/industry-news/a-holistic-approach-to-white-ink-laydown/

Article by Daywey Chen, KYMC