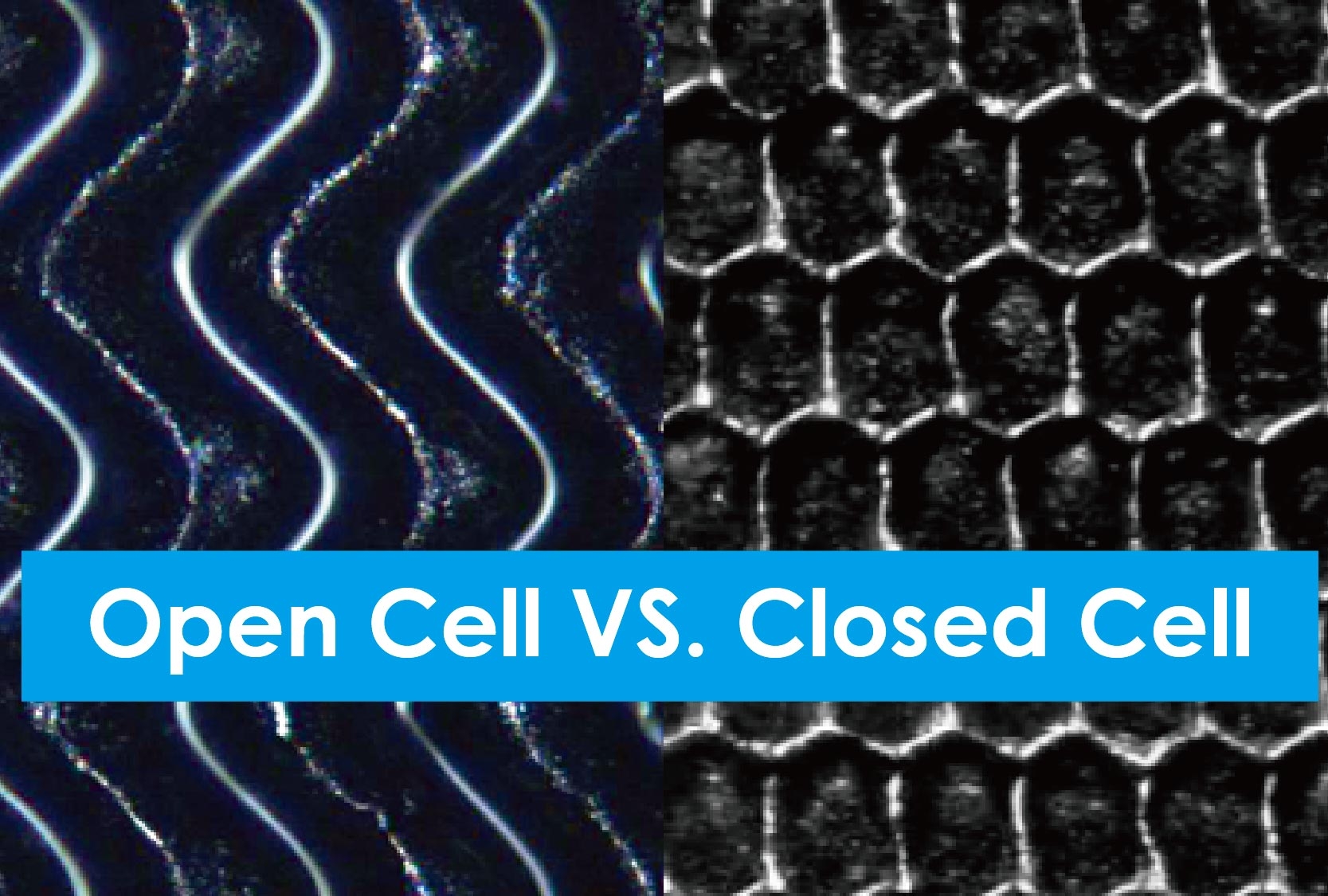

Anilox: Open Cell V.S Closed Cell

Characteristics

Open Cell System Characteristics

- To allow thick and viscous ink/ coating to flow more freely with more space.

- When compared to the closed cell system, the open cell system has fewer cell walls on the surface of the anilox, therefore adding additional ink volume with less depth.

- Open cell system in general offers a better release of the ink / coating

Closed Cell System Characteristics

- Offers more control over the ink and coating transfer when compared to the open cell system

- Has a stronger and more stable structure formation that is more resistant to score lines

Things to prevent

Ink spitting

Ink spitting commonly happens to high viscosity inks at high-speed printing. For instance, the viscosity of UV inks can be as high as 5 times higher than water-based inks. This leads to a higher chance of hydroplaning, which lifts the doctor blade by a very small amount and causes extra ink to come through the blade. As result leaving excess ink on unwanted areas. To prevent ink spitting there are many things that can be done. For instance, to adopt a stiffer(thicker) doctor blade or to adjust the doctor blade’s angle. To lower the ink viscosity level. From an anilox perspective, one should select an anilox that places down a thinner layer of ink with less ink volume. From the cell systems’ perspective, an open cell system will be able to provide a better flow of the ink, as it has fewer cell walls to contain the ink. Instead of building up the pressure and eventually forcing its way through the doctor blade onto the plate, the open cell system releases the pressure to prevent misting from happening. For a closed cell system, even though you are able to obtain more control of the ink, the pressure is more likely to build up at the doctor blade touching point on the anilox. One can try out the 60-degree elongated closed cell anilox to obtain more surface on the anilox to release the pressure.

Left: controlled condition Right: ink spitting

Source: https://www.daetwyler-usa.com/

Pinholes

Pinhole is the opposite of ink spitting. It is when insufficient ink is being laid down onto the substrate. The pinhole is caused by the insufficient transfer of the ink from the anilox to the plate. From an anilox perspective, factors such as ink drying too fast on the anilox, dirty anilox cells, and low cell volume, can all contribute to insufficient ink transfer. Therefore, when it comes to the anilox cell system, one should choose a system that has the potential for greater ink release such as the open cell system. On a closed cell system, a 60-degree cell has thinner walls, thus a larger opening for better ink release. Some commonly used closed cell specifications are between 200 lpi with a 9.5 bcm volume to 400 lpi with a 4.5 bcm volume.

Conditions

High speed printing

During high-speed printing, you would want to prevent an over-ink release. The greater the speed of the anilox rotation, the liquid ink is more likely to be driven backward within the cells. In a closed cell system, the ink that drives towards the cell wall will create a lift, causing print issues. Therefore, a rule of thumb is to select anilox with lower volume from a recommended range of 2.5bcm to 2bcm, at the same time adopting a smaller cell opening so there will be less ink to drive back causing an ink lift in each cell. If you happen to choose an open cell system, be sure to lower its ink volume and pair it with inks that have greater drying capacity.

UV ink applications

UV inks are known for their high viscosity level. Therefore, they need a better release system and a system that builds up less stress at the doctor blade tip touching the anilox. An open cell system is usually recommended for UV ink applications.

Special enhancements such as glitter, pearlescent and soft touch printing

Special printing or coating applications usually contain larger particulates in the liquid. Therefore, you want to prevent the particles from getting trapped within the cells. In this case larger cell openings in a closed cell system or an open cell system are recommended for the job.

Depending on your application, a closed cell system or an open cell system may be more suitable. In general, open cell system provides a better release and generates less pressure at the tip doctor blade that touches the anilox. The closed cell system delivers more control over the ink through its cell walls.

Relevant Reading

4 Steps to picking out the right shape for your anilox

Article by Daywey Chen, KYMC