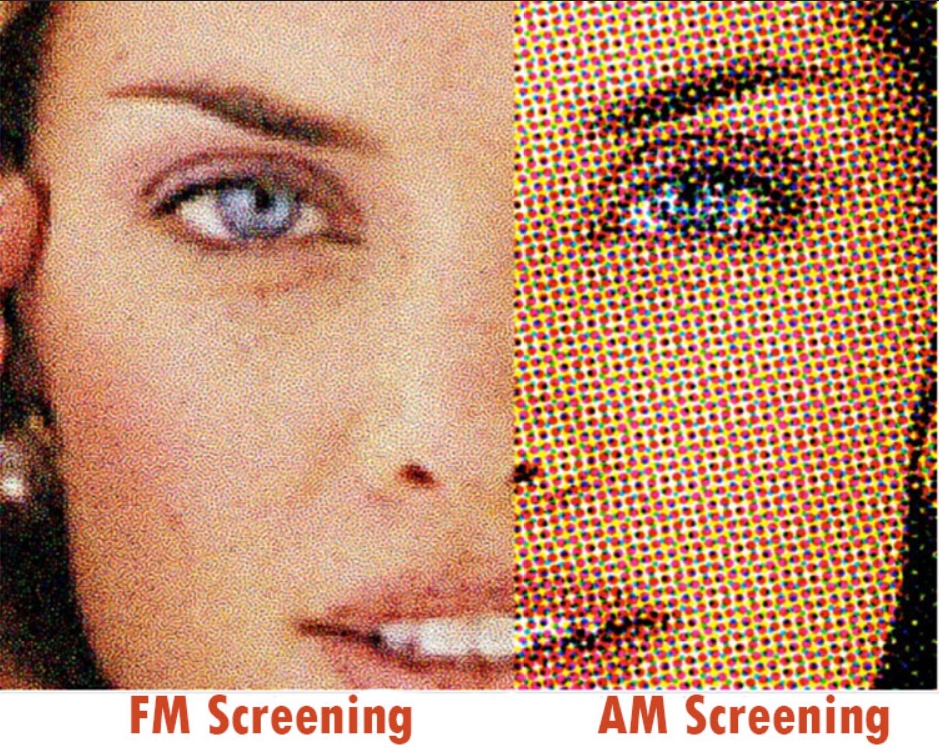

AM Screening V.S FM Screening

Delivering high definition images that are clean and sharp are the goals of every printers and brands. The print quality of a flexographic process is determined by many factors, today we discuss one of the critical factor: screening process in plate making

AM (Amplitude Modulated)

How the AM screening works?

The half tone dots in an AM screening are arranged on a grid. There are a fix number of dots on the orthogonal grid. Larger size dots are rendered to represent darker tonal values and smaller size dots are rendered to represent the lighter tonal values

Disadvantage of AM Screening

- Due to the fact that larger dots are used to represent darker tonal values, producing fine details in the darker areas in AM screening are less effective.

- As the dots are equally spaced, AM screening tends to create rosettes patterns that are visible to the naked eye.

- As dots are equally spaced, moirés is more visible to the naked eye. To minimize the moirés effect, dots are designed to be placed at certain angles. The most common angle for a CMYK 4 color process is C(75°), M(15°), Y(0°), K(45°).

Advantage of AM Screening

- Tend to work best in mid tones

FM (Frequency Modulated)

How the FM screening works?

In FM screening, the half tone dots are fixed in size. However, unlike AM screening, the dots in FM screening are arranged stochastically or randomly according to the tone value that would like to be produced. Darker tonal values are produced by placing more dots (higher dot frequency) in the region and lighter tonal values are produced by placing less dots (lower dot frequency) in the region.

Disadvantage of FM Screening

- FM Technologies amplifies dot gain

- Hard to make the transfer from film to plate during the plate making process before the introduction of CtP (Computer-to-Plate) technology.

- Midtones are harder to control in terms of how the dots should cluster. When dots connect or overlap, noise or mottle can occur.

- Unlike AM dots, by their nature, FM microdots on press resist added ink densities. As a result, it is difficult to make color or tonal adjustments.

Advantage of FM Screening

- Since FM screening utilize very small dots (usually from10 to 20 microns) to produce the images, very fine details are possible.

- As dots are randomly placed, this eliminates the screen angle problem, therefore eliminating the moirés and rosettes patterns.

- FM screening is able to create a wider gamut than AM screening

XM (Cross Modulated)

How the XM screening works?

XM uses FM screen in the highlighted and shadow areas and AM screen in the mid-tones. XM applies special technology to smoothly transition from one screen to the other. XM screens combine the best performance characteristics of both AM & FM

Conclusion

AM screening and FM screening both has its advantages and disadvantages. In general FM screening are more suitable for details images, highlights, and shadows. AM screening performs better in mid-tones. FM are more consistent in its ink delivery, therefore, some say that it is able to produce a very stable appearance. This could be good things unless your print doesn’t match your proof. When the mismatch occurs, it will be difficult for press operators to tweak the appearance on the press. As Technologies advances, the newer XM screening takes advantage of AM & FM screening to produce to better print quality.

Relevant Reading

Different Plate Making Process Discussed Inside Out

Flexographic Plate - Photopolymer or Elastomer?

Article by Daywey Chen, KYMC