Case Studies

| 標題 | 圖片 |

|---|---|

October 25, 2021 | KYMC Marketing

This month KYMC completed another 8 color Gearless CI Flexographic press (Euroflex) installation in Thailand. The adoption of flexographic printing for flexible packaging in Thailand had increased dramatically over the years. For this reason, the customer had decided to get into the game with an investment in a new gearless flexographic press. The KYMC technical capabilities for mechanical specification, registration, auto splicing, auto wash, and auto viscosity control includes...

September 3, 2021 | KYMC Marketing

What is it like to work with technology companies? How is it different from the flexible packaging industry? In this article, KYMC will share its experience from two different angles: specification requirements and commissioning criteria.

September 19, 2019 | Daywey Chen

At KYMC we found that bigger doesn’t mean better. Bigger company may have the economy of scale when it comes to mass orders. However, they often lack the flexibility of their smaller competitors. From the many printing and packaging solution providers that we have worked with. We found that having the right equipment is always a key factor to success. Drawing upon an analogy, are you using a knife to fight against a rifle? Or are you using a rifle to go against a rifle?

May 28, 2019 | 陳岱蔚

軟性電子的應用領域眾多,包括汽車,物流,可穿戴設備,醫療保健,商業展示,消費電子,遊戲,教育及包裝等。這些領域用採用印刷技術開發出HF&UHF RFID標籤,功能性基板,柔性OLED照明,可撓式HMI面板及可撓式感測器。

December 13, 2018 | Daywey Chen

The action trend taken to reduce the VOCs emission by printers across the globe varies depending on factors such as the regulation intensity of the region, the technology advancement of the region, the environmental consciousness level of the demographics. In some parts of the world, not much attention is being placed into VOCs emission reduction. In some parts of the world, aggressive measures are taking place. In general, there are three ways to treat VOCs. 1. Targeting the issue from the source (raw materials), for instance changing from solvent inks to water-based inks 2. Targeting the issue by adopting a more environmentally friendly printing process, for instance changing from rotogravure process to flexographic process. 3. To target the issue by installing VOC converting or recycling equipment.

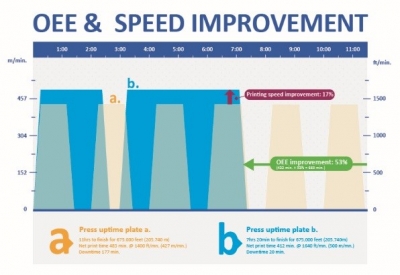

October 5, 2018 | Dr. Dieter Niederstadt

This week KYMC invited AsahiKasei to share about the factors to consider when choosing a flexographic printing plate. To draw a case study demonstrating that choosing the right plate could impact the production efficiencies in terms of printing speed and machine downtime significantly: as much as 53% in overall equipment efficiency(OEE).

February 27, 2018 | Ivan Lin

During printing as air travels back into the chamber after the ink transfer onto the printing plate, if the blade pressure to anilox roller is too high, this will prevent the air and ink from reentering into the chamber. This will cause an imbalance of air and ink flow, leading to foam generation and buildup at the back blade.

December 8, 2017 | Ivan Lin

In the printing and converting industry, one of the Industry 4.0 ideas is the communication between the different parts of the printing and converting process, enabling companies to utilize the information gathered to produce valuable actionable items in its production process, customer services, inventory management, and supplier management.

.jpg)