Heavy Duty CI Press: A tailored wide web flexo press

Typical wide web width found on the market are below 1.7 meters because a width above 1.7 meters is another realm of craftsmanship. The extreme wide web width usually makes impression control and operability much harder. To design a vibration-free printing press is fundamental for press suppliers yet highly relies on the press suppliers’ know-how and experience. Furthermore, an extreme wide web press means a large press to operate. To design the large press with ergonomic designs so that it is operator-friendly is crucial for production efficiency. Therefore, such demands place significant proof on the design and manufacturing capabilities of press suppliers.

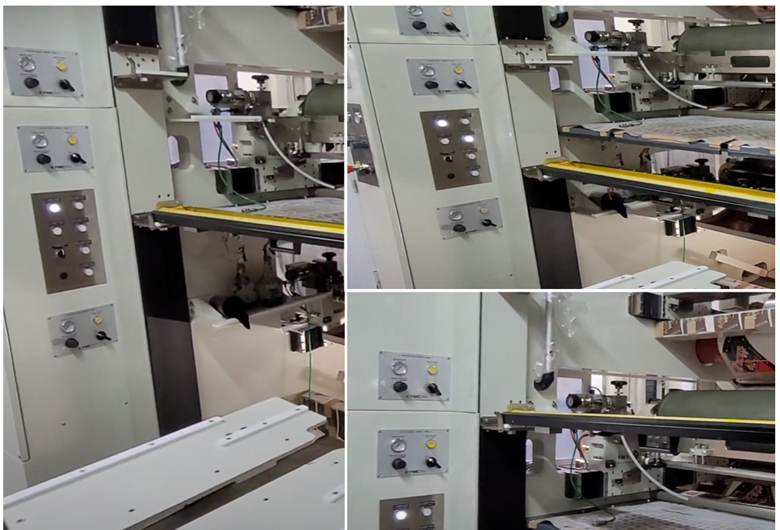

KYMC specializes in press customization. An ample experience in providing extreme wide web machines out of ordinary specification. In a recent project, KYMC delivered a 2-meter wide web CI flexo press for logistic application. The wide web press model can be applied to film or paper substrates. On a paper substrate, it can also take on pre-print jobs for the corrugated boards.

The extreme wide web press makes job changes more difficult. Changes of Plate sleeves, Anilox Sleeves, doctor blade chambers and ink could be very time-consuming and a significant challenge for the operators if there is no corresponding well-designed automation. KYMC inteIM intelligent Ink management system combines the AUTOMATIC WASH SYSTEM and the AUTOMATIC VISCOSITY CONTROL SYSTEM, including dynamic ink pumping control, on press wash up, and on press ink viscosity control. InteIM brings the benefits of quick job change, reduced washup cost, reduced labor cost, and even the most essential feature - stable and well-controlled pressures of inking to the chambers. Alongside the automation of the inking system, the accessories such as the handling tool for printing sleeves and anilox sleeves also need to be tailored and well-engineered. In order to achieve operational convenience, KYMC provides the solution with a special sleeve trolley and elevator for sleeve changeover.

The extremely wide doctor chamber is a challenge as well during job change. Therefore, a motorized lifting elevator is designed to prevent the operator from having to lift the chamber manually.

A wider web also means more waste will be created during a production setup. Therefore, it becomes a must to optimize the print setting in the shortest time. To accomplish this, a smart impression system and a smart register system are equipped with the CI flexo press to set the 1. anilox to printing plate pressure 2. printing plate to impression roller pressure 3. register between each color according to the best image produced. The optimal print setting could be achieved and the waste to be minimized to the lowest.

At KYMC we believe that machine specification should be tailored to the production need and not the other way around. Therefore, KYMC has devoted many resources to designing customized machines that can operate as stable as a standard machine. To fulfill customers’ needs with a solution that is customized, yet stable and precise.